Christian Greiter

Managing Director

Tel.: +49 831 / 56419-0

Write a message

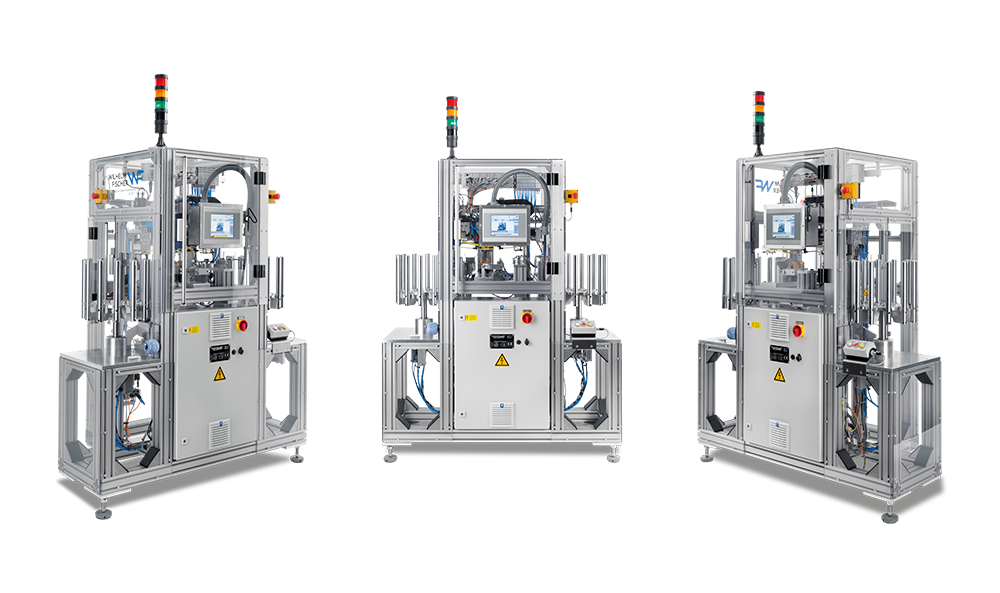

More than 20 years of experience in the automatization of industrial processes - we design efficient and reliable solutions for your process. From planning and software design to manufacturing, assembling and start-up - a “one-stop-shop” for all your needs. We conceptualize and build complete systems for the highly automated mounting of precision parts - from part separation to final quality check and laser marking. For the automatic quality check of parts, e.g. Aluminum profiles, we develop special machines that can measure geometric properties (flatness, parallelity, angularity, length) and test the hardness. This allows you to separate non-compliant parts in a fast, safe and fully automated process.

Our core competences

Software

Versatile machines - easy operation. Our software makes it easy to operate complex machines and meets all the needs and expectations of our customers: www.wilhelm-fischer.de/software